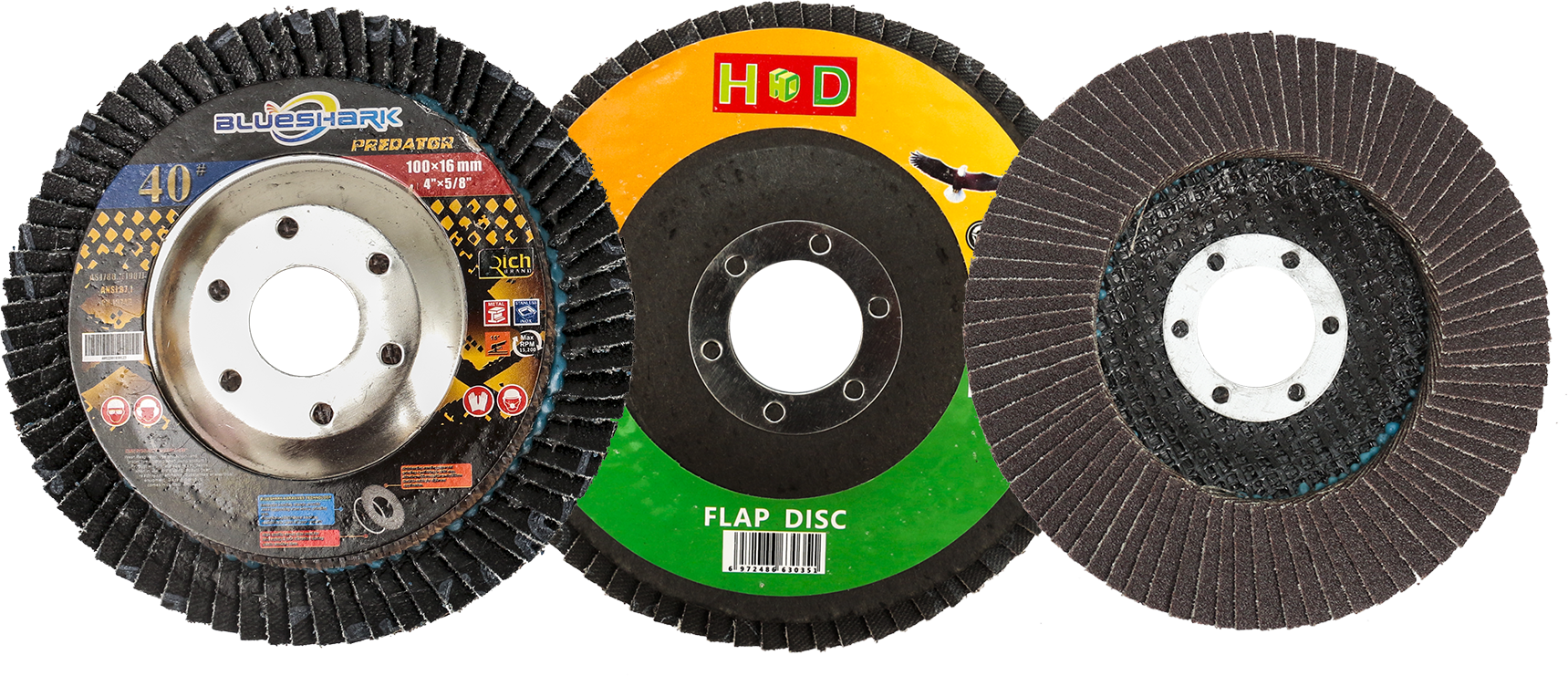

Cutting Disc Flap Disc Grinding Disc

Blueshark & HD Flap Discs provide a system for removing material and finishing in one step, thereby, reducing both finishing time and finishing costs. Use in applications such as weld grinding, debarring, rust removal, edge grinding, and weld seam blending. It can be easily adapted to most right angle grinders.Cutting disc in srilanka, abrasive products in srilanka, abrasive suppliers in srilanka, cutting wheel, cutting wheel in srilanka, PE+ cutting disk, PE+ cutting wheel, abrasive wheels in srilanka, Griding Wheel

Rich Brand Abrasive Network Supplies High-quality Flap Discs

Rich Brand Abrasive Network deals only with high quality abrasive products. It has a long life and good grinding efficiency. Taking advantage of the special production technology, it has good performance in stainless steel gate, oxide skin, and welding spot. Blueshark & HD has high sharpness, long service life, and good synchronization.

Application of Polishing Flap Disc

Flap discs offer right angle grinding versatility with a product that can grind and finish in a single operation. The abrasive flap disc adheres to a rigid backing plate. It is the back plate that provides stability during operation with cooler cut, less vibration and smoother finish without gouging. Polishing flap disc is well-suited to stock removal through blending applications. It is widely used in metal processing industries such as daily hardware, tank processing, automotive, train, and shipbuilding. It is mainly used to remove the oxide layer, rust, solder joints, etc. from the surface.

Flap disc application is divided into two major fields according to the metal type. One field is ordinary metals, such as general steel, iron, and so on. In this application field, generally ordinary abrasive grains can meet the grinding requirements. The other field is High hardness metals, such as stainless steel, titanium alloys, etc. Due to their mental characteristics, difficult to grind, easy to burn, high metal viscosity, etc., ordinary abrasive grains are difficult to meet the requirements. We need to use some special abrasive grains, such as zirconium corundum, ceramic abrasives, etc.